February 8 - 14

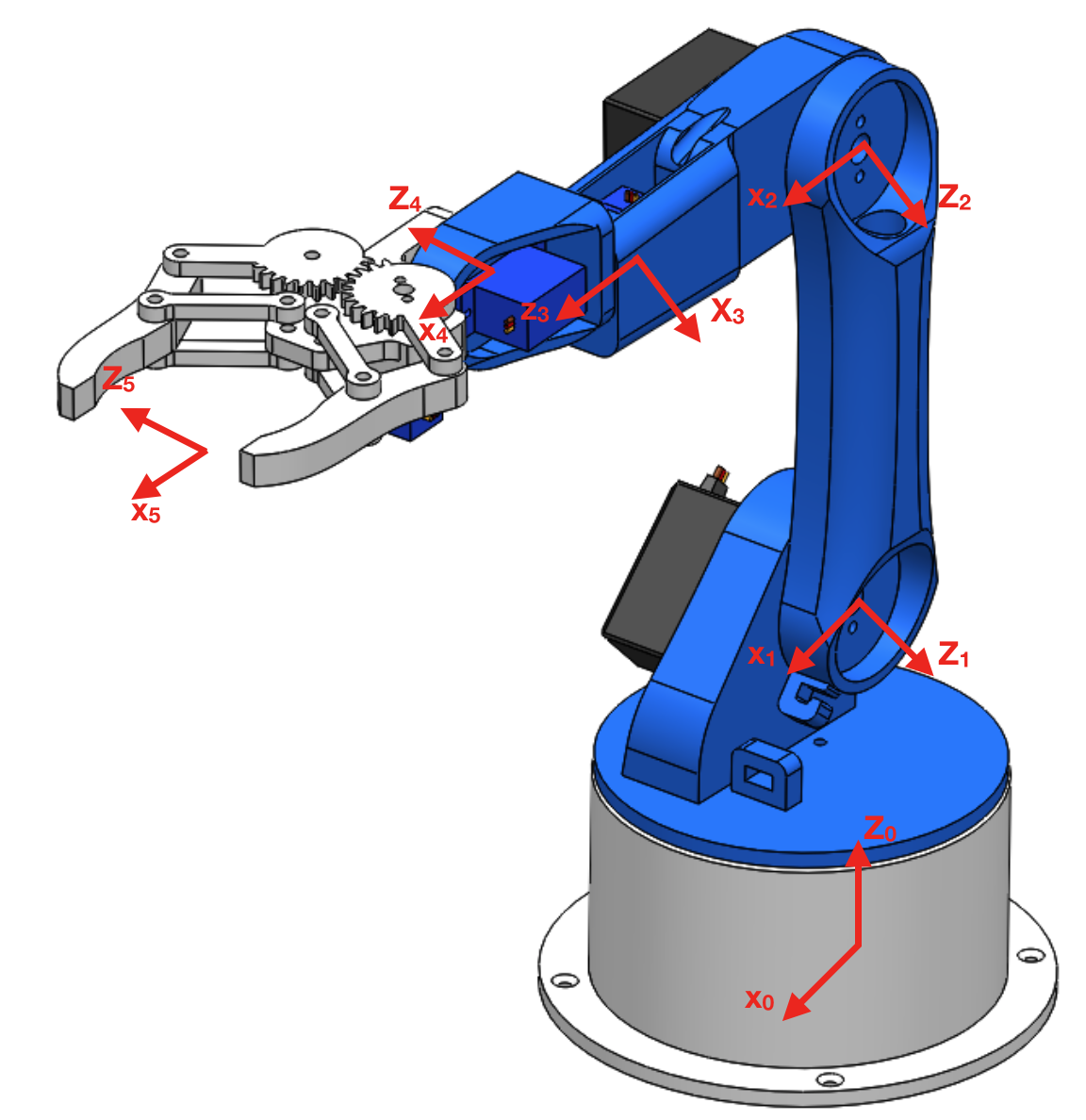

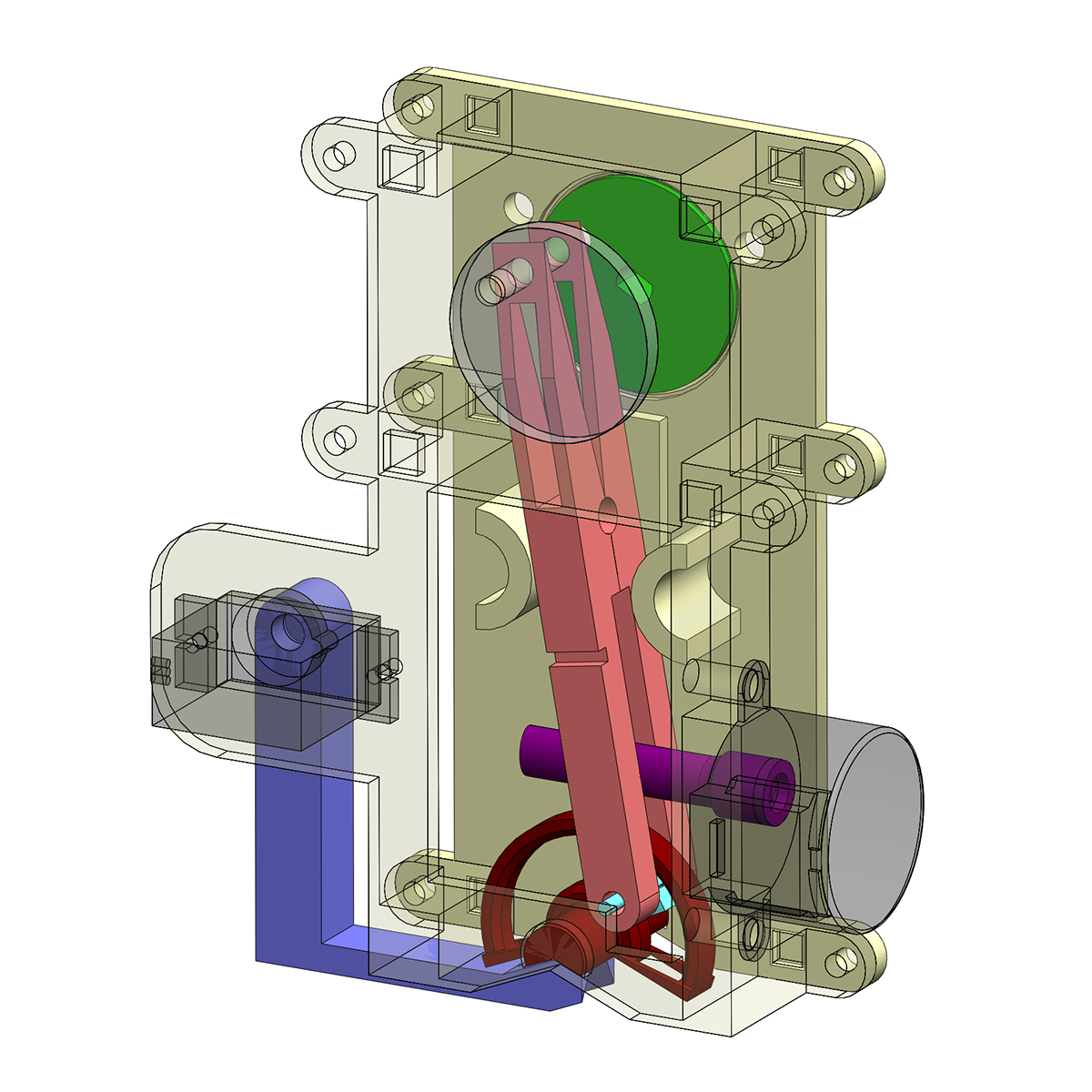

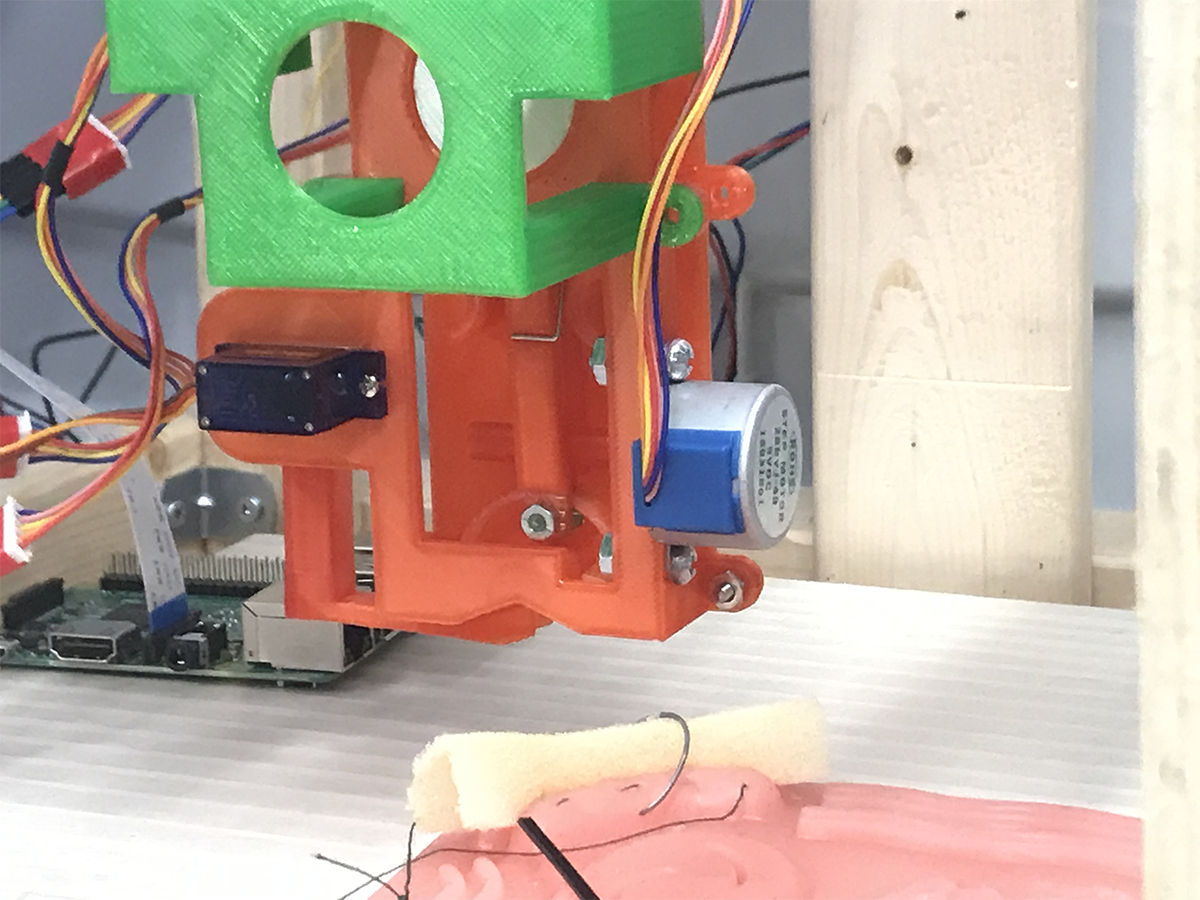

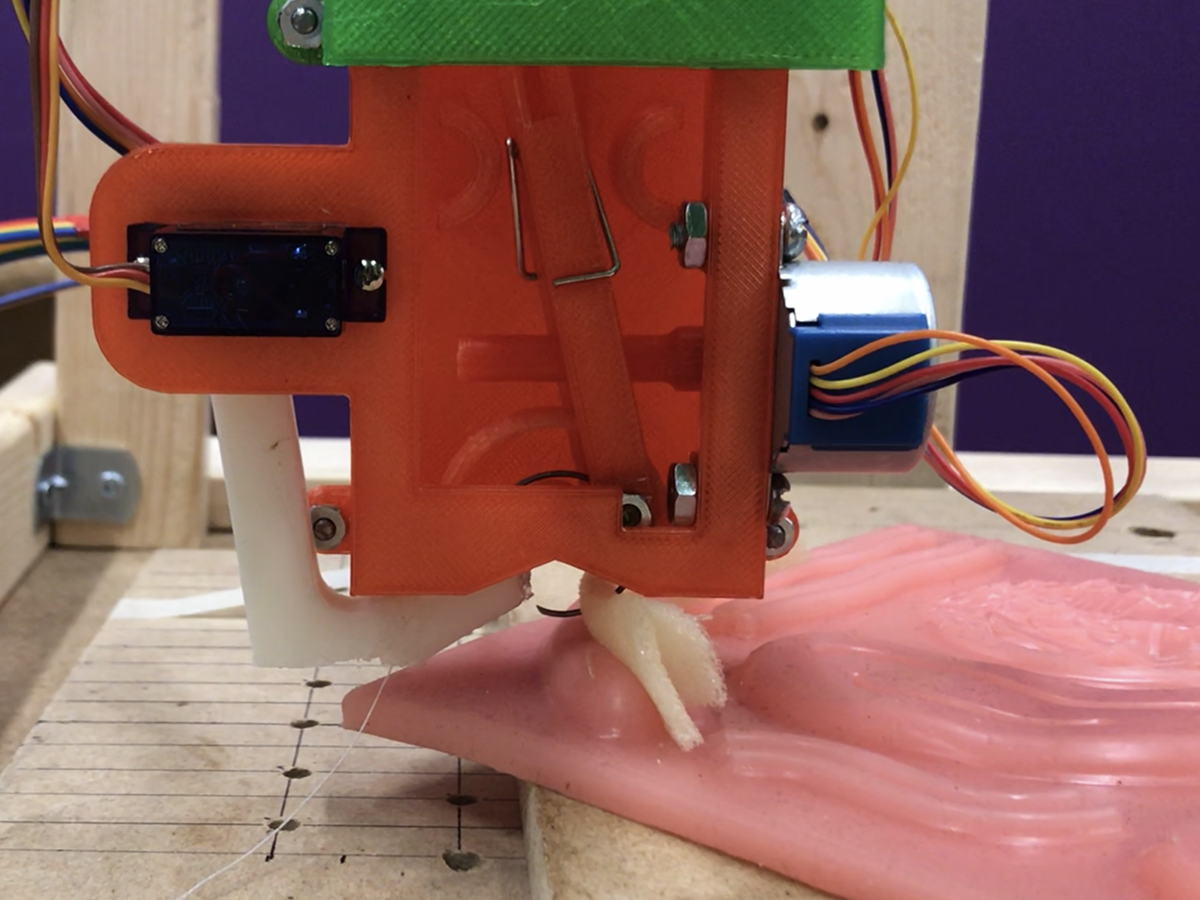

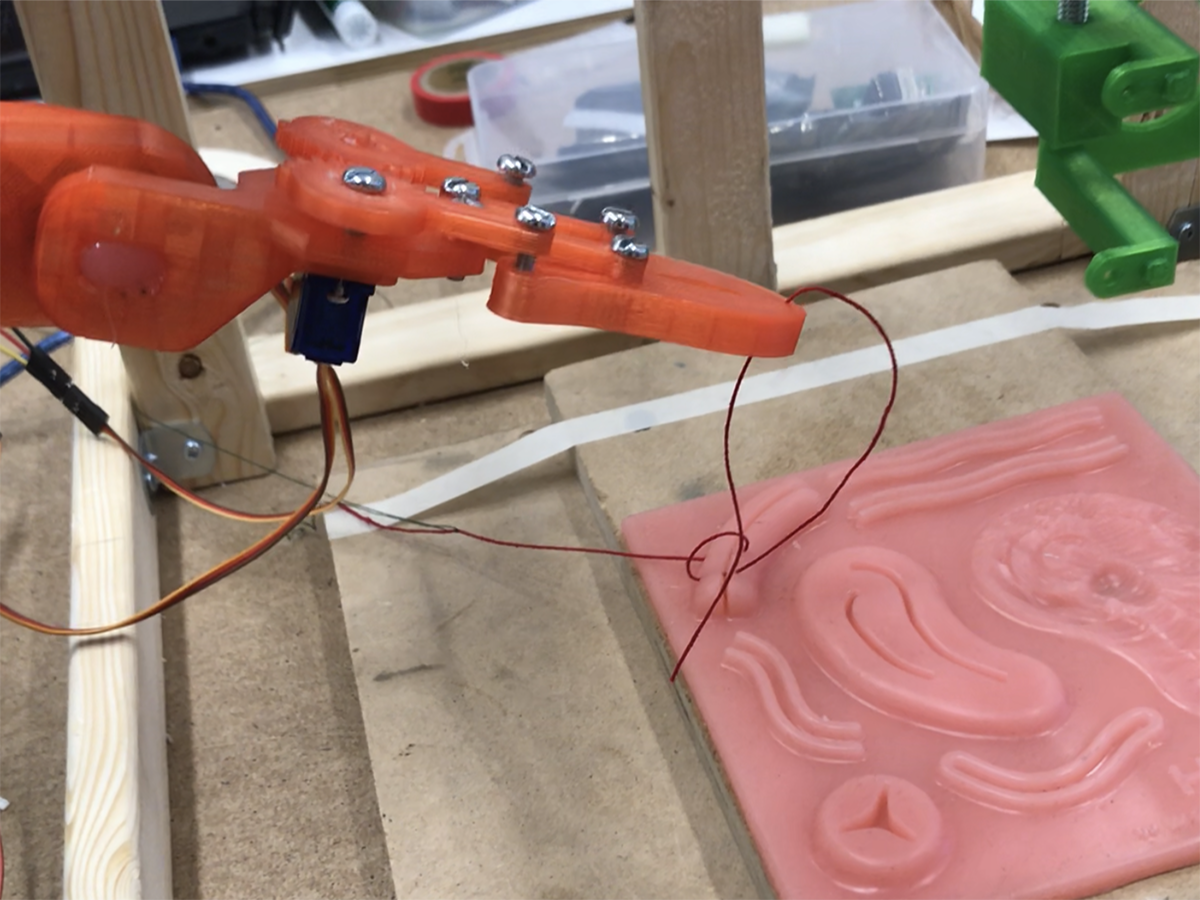

A second robotic arm, whose purpose is to handle the suturing threads, was implemented with six degrees of freedom. During

the knot-tying step of a suturing procedure, the arm will be manipulated such that its gripper is within reach of the

loose thread near a wound. The gripper will hold the thread while the suturing mechanism creates a loop. To fasten the loop

into a knot, both the suturing mechanism (its position being controlled by the gantry robot) and the articulated arm

will move in opposing directions. To be able to easily manipulate the gripper to a specific coordinate, the articulated arm

was modelled using algebraic inverse kinematics to resolve the x, y, and z positions in terms of specific joint angles.

Image (Left): Newly Designed CAD Assembly of the Articulated Secondary Arm.